Physics and Design

of Complex Fluids

My group focuses on developing principles and improved design methodologies for complex fluids and soft materials. We implement these design insights for the creation of new, innovative applications and solutions in the areas of foods, pharmaceuticals, and biologically relevant materials.

Rheology and the physics of materials are used to explain and predict the phenomena we experimentally observe. We strongly believe in the power of collaboration and diverse viewpoints for creative problem solving. Our most innovative and valuable contributions have come—and will continue to come—from connecting to new and unexpected subject areas.

Designing Yield-Stress Fluids

Many of our research projects involve “yield-stress fluids”, materials which exhibit extreme shear thinning, transitioning between solid-like and liquid-like at a critical applied stress. Yield-stress fluids are currently the most utilized and perhaps most useful class of complex fluid. Existing applications span many orders of magnitude in yield stress, and include consumer products such as hair gel and toothpaste as well as 3D printing inks and drug delivery materials.

Past research has contributed towards the paradigm of design-thinking for yield-stress fluids. In a collaborative review article, we presented a framework for “design with” and “design of” these materials, organizing and discussing the current scientific understanding to address the rheology-to-structure inverse design problem.

Designing with a material involves determining what rheological properties are needed to achieve a target performance. Design of a material in-turn considers what material microstructures might achieve a set of target properties. This framework supports and motivates research into applications like direct-write 3D printing, and complex properties like high-extensiblity.

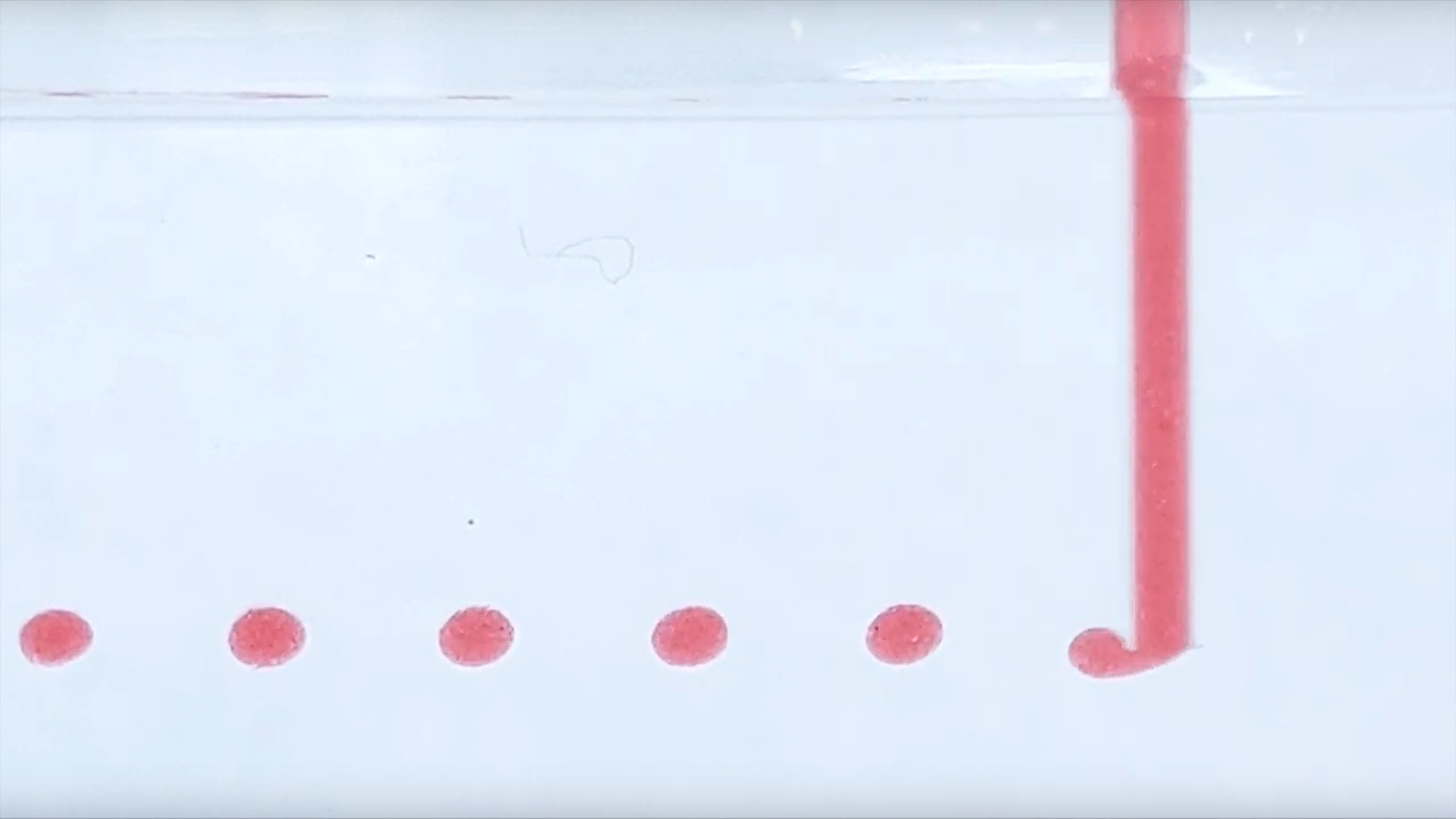

Embedded droplet suspensions

A current area of research is primarily motivated by applying principles of soft matter to the processing of pharmaceutical drugs.

Applying a framework for yield-stress fluid design and creativity, I led the development of a new microfluidic method which is the first to utilize yield-stress fluid behavior to generate and manipulate droplets in a conventionally unattainable, undisturbed state. Embedding droplets in yield-stress fluids provides an environment in which they are spatially isolated from each other and solid surfaces and in which there are no exterior convective flows; ideal conditions for sensitive processes like pharmaceutical crystallization.

Embedded droplet printing is a platform that extends beyond pharmaceutical manufacturing. The ability to print and process droplets that are suspended in place is powerful and has also been applied to chemical and biological experimentation. Supporting these applications is our continually developing understanding of the fundamental physics of droplet formation inside yield-stress fluids, and a toolbox of operations for the processing and manipulation of embedded droplets. Expanding this fundamental understanding and developing the platform of embedded droplet printing for new applications is an ongoing research focus